PDC Quick Links

Reference Documents Navigation

Documents for Design and Construction

Strategic Space Management: Principles, Process, and Guidelines

Design Standards ("Yellow Book")

Interior Signage Standards and Guidance

Exterior Signage Standards and Guidance

GT Building Name Metal Signage Standards

Building Information Modeling (BIM) Requirements

Building Information Modeling (BIM) Execution Plan Template

GT Archive Closeout Procedures

Guide for Completing Archive Entry Sheet

Video Guide for Completing Archive Entry Sheet

Video Guide for PMs on Completing Intelliport Spreadsheet

Contract Preparation Checklist

Phase 2 – Uniformat Bid Form (Ground Up)

Phase 2 – Uniformat Bid Form (Interior Renovation)

Phase 2 – Uniformat Master Key/Explanation

Statement of Constructability and Qualifications Form

Task Order Contract Submission Checklist

Task Order Template Estimate Summary & Bid Trade Analysis Sheets

(text and background only visible when logged in)

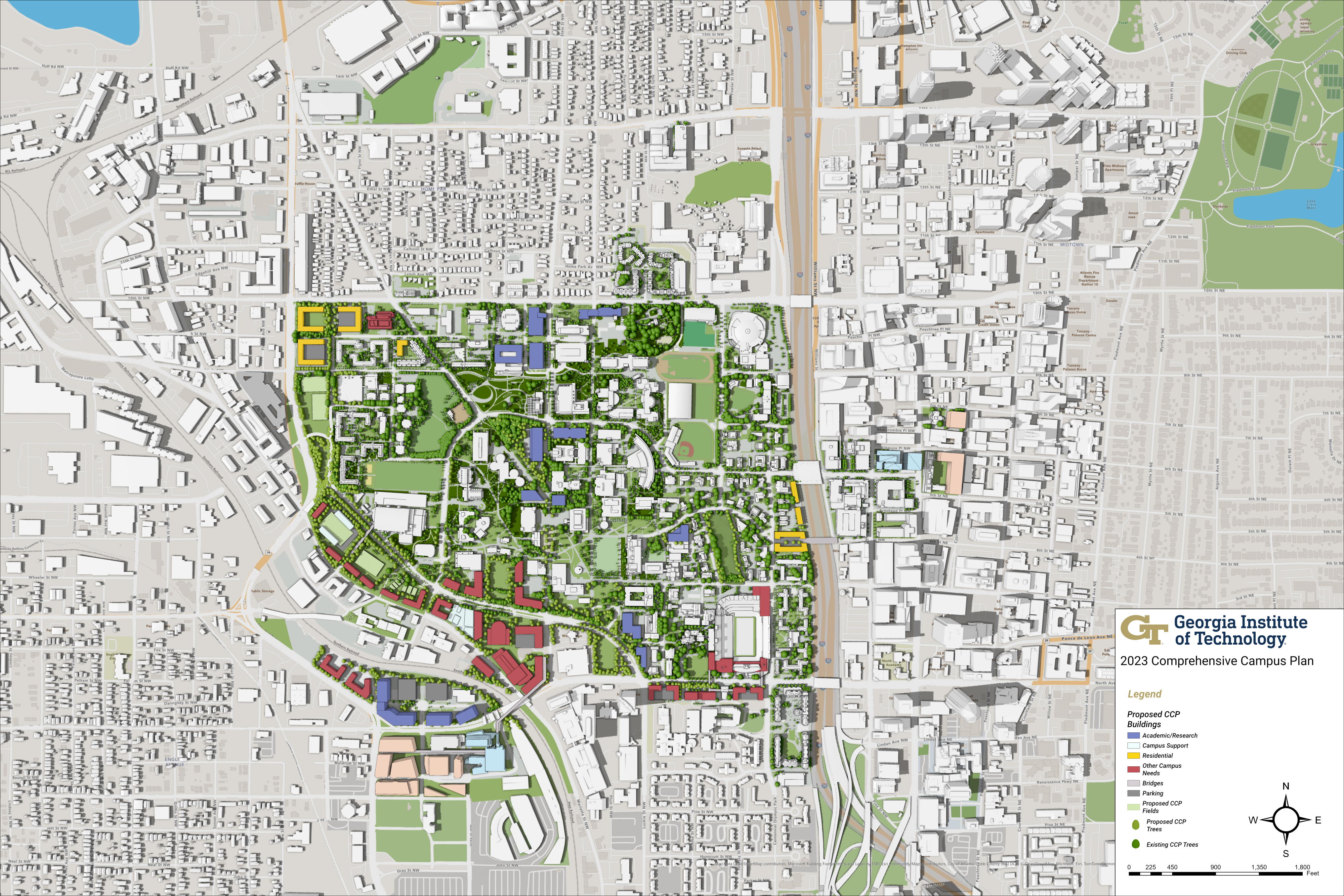

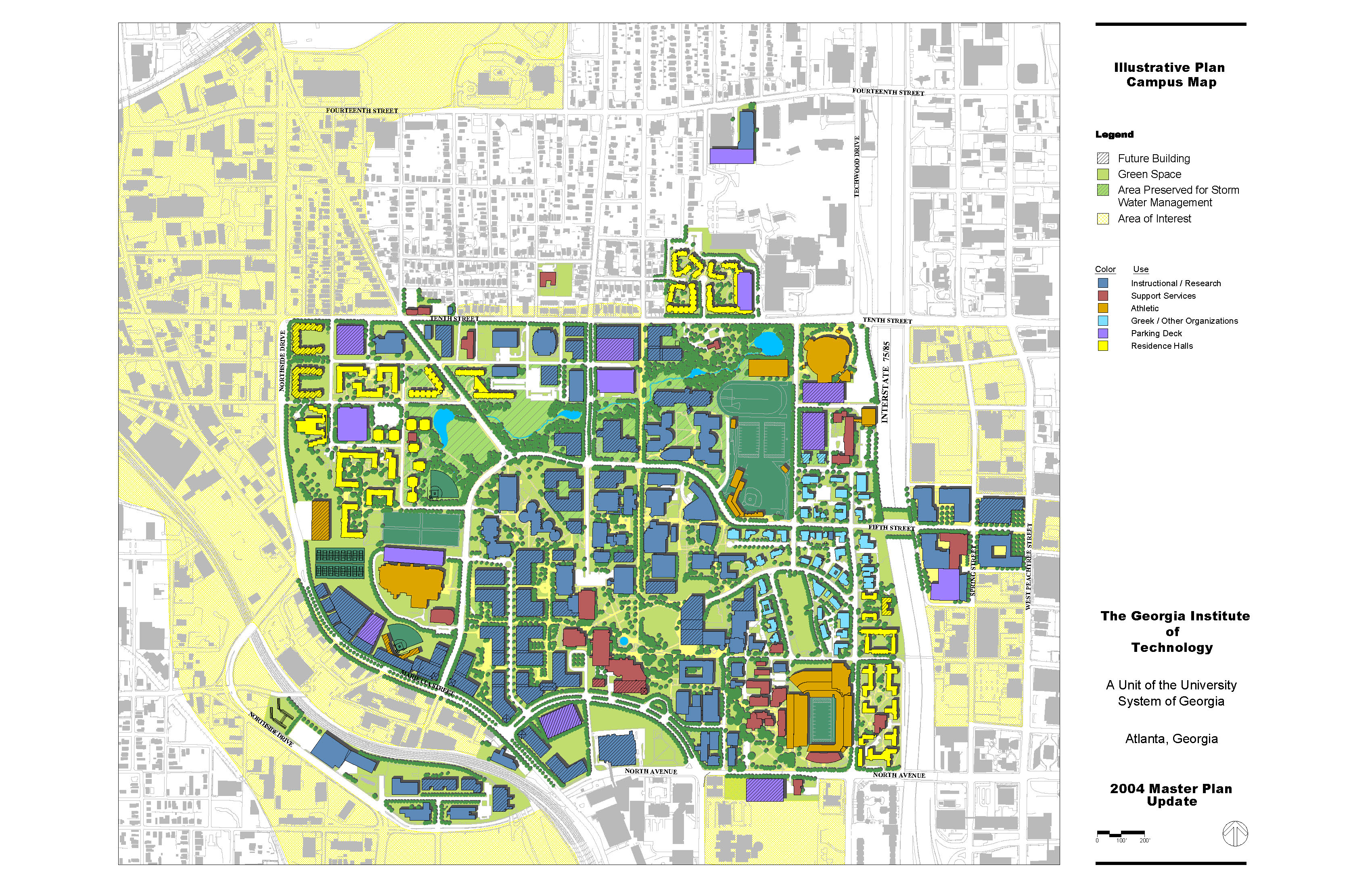

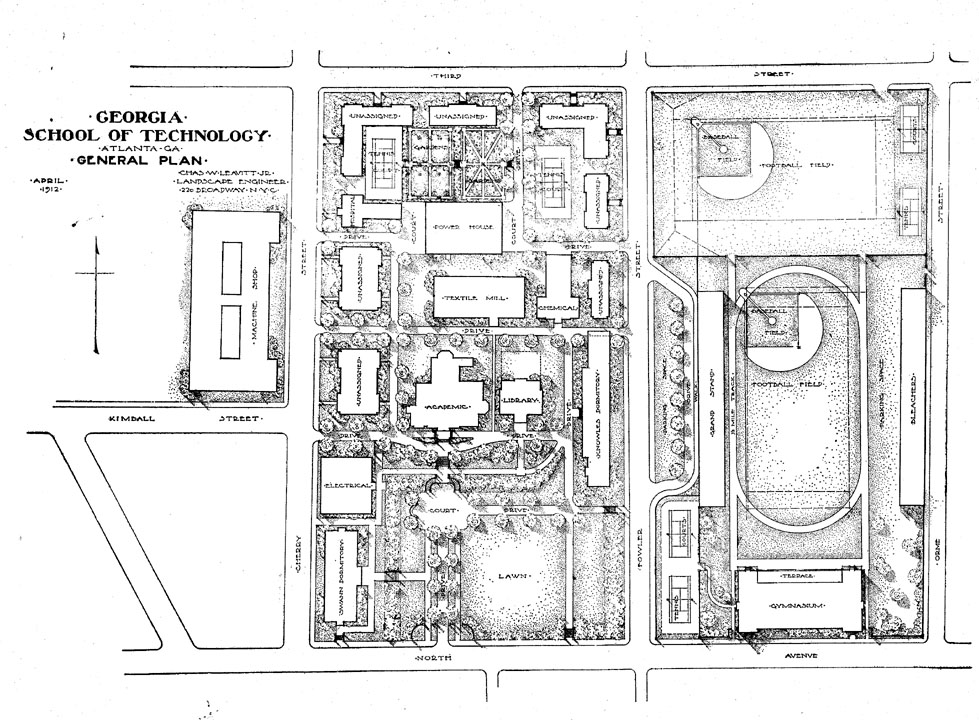

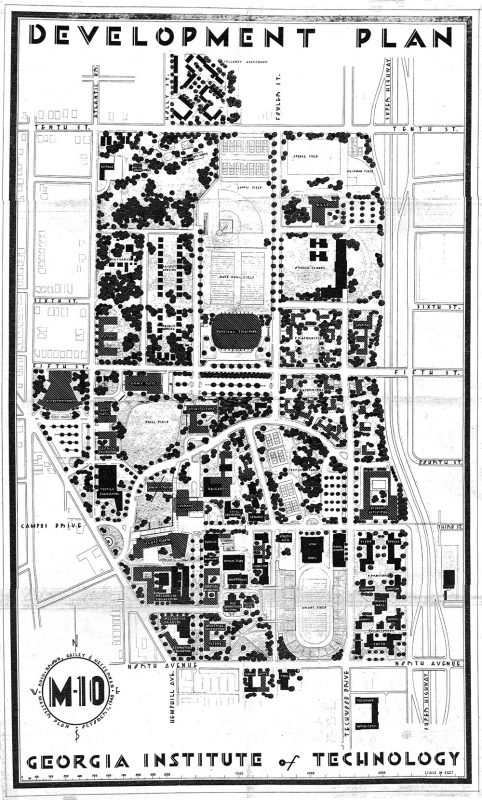

Campus Plans

Lab Design Guide

This guide aims to provide a comprehensive set of guidelines and best practices for design professionals and contractors involved in the creation and renovation of laboratory spaces at Georgia Tech.

- Georgia Tech Yellow Book Design Standards

GT Yellow Book (2021) - EHS Procedures for Laboratory Moves, Decommissioning & Commissioning

EHS Lab Moves Guide - EHS Biosafety Manual – Policies and Procedures (April 2014)

EHS Biosafety Manual - EHS Lab and Chemical Safety

Dangerous Gas Monitoring Program (DGMP) Manual - EHS Laser Safety Policy Manual

Laser Documents - GT Laser Lab Design Guide

- Vendor Resources – Planning, Design, and Construction

Vendor Resources. - Plan Submittal Form Checklist

FSO Plan Checklist - University System of Georgia (USG) Design Criteria for Laboratories

Design Criteria For Laboratories

Georgia Tech Responsibility

Before starting any lab design or construction project, Georgia Tech has key responsibilities to ensure safety, compliance, and functionality.

- Identify appropriate lab spaces based on research needs and existing infrastructure.

- Ensure the presence of appropriate Dangerous Gas Monitoring Systems (DGMS):

- Types on campus include: Honeywell standalone, Honeywell & Fire Panel Hybrid, and DGMS Panel – Notifier 3030.

- Labs must be located in buildings equipped with an appropriate DGMS.

- Review the Fire Alarm Control Panel with the Fire Safety Office (FSO) to ensure fire safety integration.

- Coordinate with Environmental Health & Safety (EH&S) to confirm DGMS requirements.

- Assess the condition of building utilities and infrastructure with Engineering.

- Match lab requirements with available utilities (e.g. 480v power, house gases).

- Include an Asbestos Containing Material (ACM) survey if one isn’t already available.

- Follow EH&S procedures for lab moves, decommissioning, and commissioning.

- Consult the Biosafety Manual for guidelines on moving lab equipment.

- A new Principal Investigator (PI) or chemical inventory requires code compliance updates.

- Labs must be equipped with an automatic extinguishing system (wet or FSO-approved alternative).

- Chemical inventories exceeding 4 liters (1 gallon) must comply with NFPA 45.

- Chemical quantities over 4L or 1 gal must comply with NFPA 45 codes.

- Quick response fire sprinklers required.

- PI to complete Chemical Inventory Spreadsheet.

- Chemical quantities over 4L or 1 gal must be listed in the chemical inventory

- Chemicals (liquid or solid) with hazard ratings that are handled or stored: health — 2, 3, or 4; flammability — 2, 3, or 4; or instability — 2, 3, or 4.

- All gas cylinders must be listed.

- PI to complete GT Equipment Inventory spreadsheet.

- Compare largest equipment footprint with size of proposed lab.

- Confirm available building utilities with equipment needs.

Design Professional Responsibility

Design Professionals are accountable for meeting safety codes and aligning with Georgia Tech standards during pre-design and construction.

- Review and comply with the USG Design Criteria for Laboratories

- Review and comply with the Georgia Tech Yellow Book Design Standards.

- Comply with the Yellow Book building-specific laboratory controls requirements in the following buildings:

- Ford ES&T (147) Building

- U.A. Whitaker (165) Building

- Comply with the Yellow Book building-specific laboratory controls requirements in the following buildings:

If compliance is not met in any section of the USG Design Criteria for Laboratories or GT Yellow Book, the Design Professional must submit a variance request. Refer to EH&S Guidance Document for Requesting a Lab Variance from the Board of Regents.

- Conduct a thorough review of the chemical inventory to comply with NFPA 45 requirements

- Review NFPA 45 State Fire Marshal modifications

Lab Unit Fire Hazard Classification

- Determine fire hazard class

- Comply with the requirements of the fire hazard class

Safety Data Sheets (SDS)

- Chemical SDS hardcopies are not required.

Flammable Storage Cabinets

- Cabinets do not require venting per Fire Safety Office.

- A statement at each flammable storage cabinet indicated in the drawings denoting the amount of material being stored as referenced from the Chemical List.

- Piped Systems: Stainless steel with mechanical joints (Swagelok) or Orbitally welded joints.

- Code Compliance: Identify when specific piping materials are required.

- Cylinders: More than 4% Hydrogen (H2) in a gas mix considered dangerous and requires monitoring. H2 does not need to be inside a gas cabinet.

- A emergency gas shutoff button is required for two or more gases outlets per NFPA 45 State Fire Marshal modifications.

- Include shut-off for two or more gases that serve a experimental equipment per GT Fire Marshall.

- Gas shut-off is not required for inert gases per GT Fire Marshal.

Dangerous Gas Monitoring System

- Coordinate with EH&S on the DGMS toxic gas alarm Georgia Security dialers

- Ford ES&T Dialers: (4) Georgia Security dialers that should be in test when working with DGMS at ES&T 03-1501; 03-1901; 03-1633; 03-1640

- Fume Hoods

- Select between variable or constant air volume based on the building's exhaust systems.

- Ensure ASHRAE 110 testing (see below) for all new fume hoods.

- Air Valves

- Material selection must meet code and PI research needs.

- Approved materials: Aluminum, Stainless Steel, Baked Phenolic Coated.

- Fume Hood Chemical Exhaust Ducts

- Welded stainless steel construction.

- Slope exhaust ducts back to the hood.

Fume Hood Certification (ASHRAE 110)

- Required for:

- New installations

- HVAC modifications

- Service adjustments inside the hood

- ASHRAE Testing Procedures:

- Face Velocity Measurement – Average airflow reading.

- Smoke Visualization – Observing turbulence at the front.

- Tracer Gas Test – Sulfur hexafluoride contamination detection.

- ASHRAE Test Types:

- As Manufactured (AM): Factory testing.

- As Installed (AI): Post-installation, empty hood testing.

- As Used (AU): In-use testing with equipment.

Gloveboxes

- Test fit with shop drawing layout.

- Purge exhaust material must comply with code and PI research.

Vacuum Pumps

- Sch 80 PVC recommended as a cost-effective solution for exhaust.

- Specify chemicals involved.

- Selection must meet PI's vacuum level and flow rate needs.

- Confirm oil-less, diaphragm technology specifications.

- Define pump exhaust and fume hood base cabinet exhaust setup.

Snorkels, Task Exhaust and Point-of-Use Ventilation

- No in-line fans or back-draft systems.

- Classified as Class I, II (A1, A2, B1, B2), or Class III.

- Reference: Biosafety Cabinet Guidelines (Biosafety Manual by EH&S).

Casework and Fume hoods should match building standards. Consult with the GT PDC Project Manager on the specification, material and color selections.

- Eyewash: Cold water supply only. No mixing valve required.

- Emergency Showers: Tepid water required. Cold and hot water supply with mixing valve. Modesty curtain required.

- Design Standards: Review GT Yellow Book Design Standards (by Design and Construction).

Radiation and Laser Safety

- Class 3B and 4 Lasers: Follow GT Laser Lab Design Guide (Rev 01, EH&S).

- Lead Shielding

- Door Interlocks

- Lab Stools: Quantities determined with PI. Stools provided by Georgia Tech.

- Glass or Marker Boards: Supplied by Contractor.

Lab Design Questions?

Contact: Ngugi Mathu

Registered Architect III

470-428-0160

ngugi.mathu@facilities.gatech.edu

(text and background only visible when logged in)